built on the

principles of

trust and commitment

We at JCBL always remain committed towards total satisfaction of our Customers, Associates, and Society at large through the continual improvement in our Quality Management System. Quality is always paramount to us and we always ensure that only the best quality products reach our stakeholders.

This is achieved through:

- Excellence in manufacturing technology

- Value for money

- On-time deliveries

- Continual improvement through audits

- Commitment for safe working

- Protection of environmental conditions

- Conservation of natural resources

- Compliance with all applicable legal and other requirements

Key elements of our quality control process:

- Qualified team of Engineers in every domain.

- Certified Engineers who handle specific type of manufacturing processes and testing.

- To ensure the highest product quality, all manufacturing processes are validated at regular intervals by doing internal audits of processes.

- Government approvals for every product we manufacture.

committed to zero errors

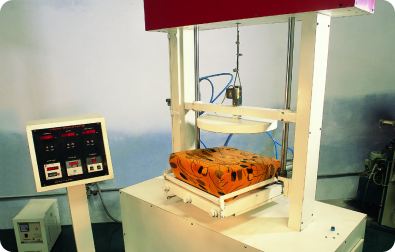

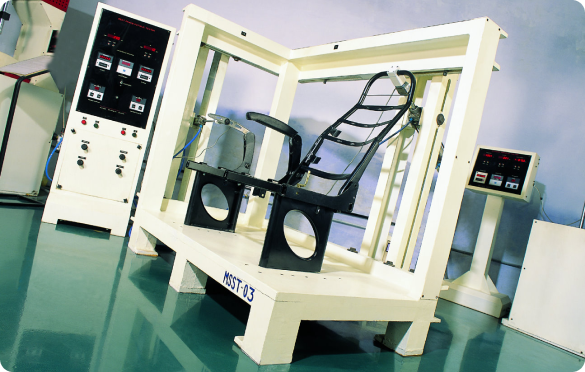

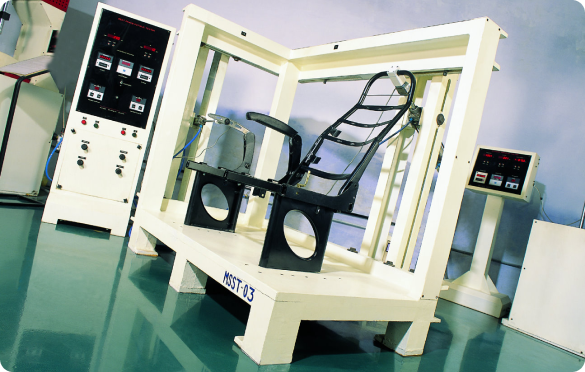

Our Testing Facilities

- Dimensional/Functional Tests

- Dye Penetration Test at Critical Joints

- Hydrostatic Leak Test

- Paint and Surface Roughness Test

- Primer Coating DFT Test

- Adhesion Test

- Hook Lift Test

- Interchangeability Test

- Hydraulic Tests

- Chemical and Mechanical Property Test

- Percentage Gloss

- Fatigue Testing

- Resistance to Spread of Fames

- Smoke Density

- Toxicity

- Roll Over

- Shower Test

- Pneumatic Pressure Test

- Hydraulic Leak Test

- Pressure Impulse & Vibration Test

- Minimum Burst Pressure Test

- Make & Break Test

- Temperature Cycling Test

- Helium Test

- Tensile Strength

- Flexural Strength

- Izod Impact Strength

- Compression Strength

- Water Absorption

- Hardness Test

- Glass and Solid Content